Management of a fleet of equipment

You have a fleet of equipment and you seek to manage it centrally by continuously monitoring the status and position of each equipment

Need: management of a fleet of equipment

All companies have a fleet of equipment and its maintenance is quite expensive :

- Society in the tertiary sector: computer equipment (computers, printers, etc.)

- BTP: construction machinery, tools

- Buildings: security equipment, heating, air conditioning, access management equipment

- Warehouses: lifting machines, packing, conveying

- Production or operating plant: industrial machinery

- Provision of technical services: intervention vehicles, tools

- Energy operation: transformers, motors, compressors, valves

The unavailability of equipment can simply lead to additional operating costs but also a loss of turnover if the direct activity is impacted.

Companies, therefore, seek to optimize the management of their equipment in a simple and efficient way:

- have an accurate and detailed inventory of all equipment

- know their precise location

- monitor the condition of each equipment

- Know the history of crew maintenance and use of equipment

The additional requirements complement this: documentation of the material, adding the procedures…

The control of this data aims to improve the safety and availability of the material stock.

Implementation of the UBLEAM solution

A digital tool to efficiently manage your assets

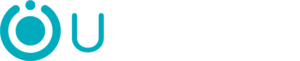

The UBLEAM solution is designed to manage hardware data through its built-in, customizable database. It is simply configurable either by manually creating each equipment via the web back-office or by importing an Excel standard file containing the list of equipment and their attributes. It is also possible to interface Fusion directly with existing software (CMMS, ERP, GIS, etc.) by using the Fusion web services (API) to synchronize data automatically.

Attributes example:

- serial number

- last maintenance date

- status

- localisation

- etc…

Fusion simply helps you customize bleams, print them and deploy them in the field as described in this article. Once deployed on the objects, it is then enough to pair them with the mobile application UBLEAM.

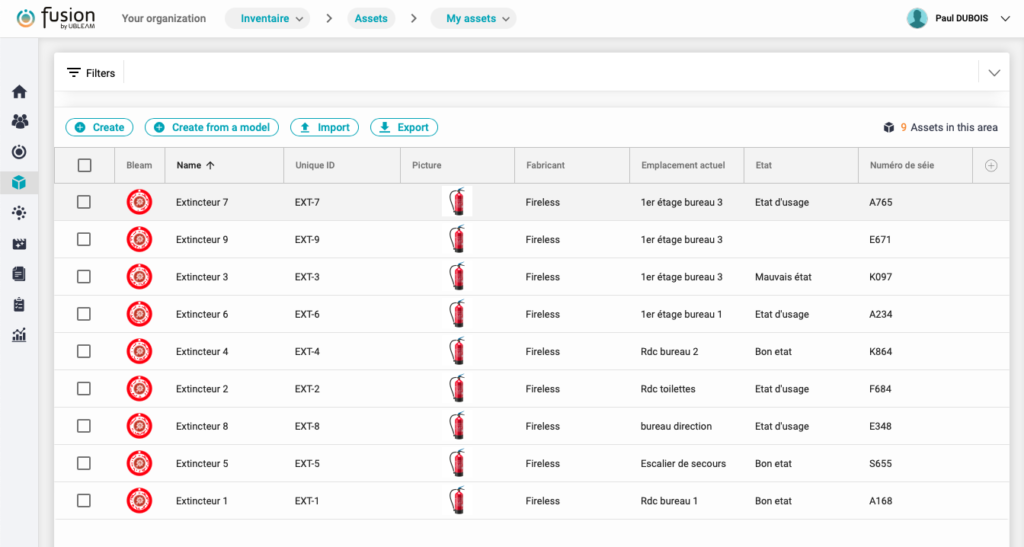

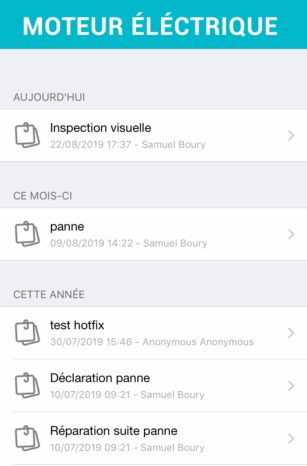

For the configuration of mobile services, the generic functions available and configurable in the Fusion back-office are more than enough to address the needs:

Cover

to display equipment name and number

Géolocation

at the time of the scan of the phone

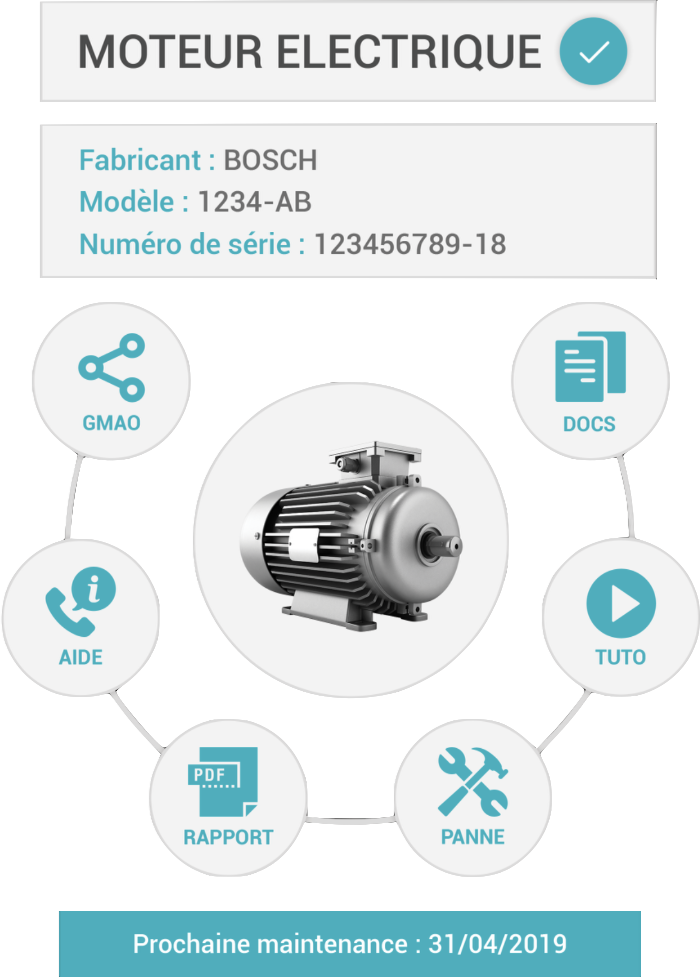

Note-taking

button to enter notes and take notes

Logbook

button to retrieve the entire history of notes on the equipment

It is possible to go further by directly configuring the editing of attributes (status, last maintenance date, etc.) directly via mobile forms, sending email alerts when thresholds are exceeded,…. and this in a scalable way from the base configuration of Fusion.

Advantage of the UBLEAM solution

No more lost reports, no more paper, finally a lasting solution

Paper-based reporting is the one-size-fits-all solution, but it takes time for officers to capture information and is not very sustainable. Reports are often lost in a drawer.

CMMS solutions (including cloud, mobile and a tagging tool such as QR code or NFC) remain more expensive than Fusion and less intuitive. They remain focused on maintenance management while Fusion aggregates all material data (production, logistics, service provider monitoring,…).

With the upcoming arrival of the equipment search in augmented reality, Fusion has all the advantages to be the centralized management solution for your hardware.

Some customers in this use case :

Interested by our solution ?

Our experts will be happy to chat with you!